RePaint The STARSMeisei Electric's Space Technology

Repaint the future of space.

Meisei Electric's space technology

Introduction

In 1954, the first step into space changed the future.

Meisei Electric's space challenge began with Japan's first rocket engine test in 1954, and is still running around infinite space at this very moment, continuing to support the quest for knowledge. Meisei Electric's cutting-edge technology is expanding its field of activity into space, including participation in domestic and international planetary exploration projects, development of nanosatellites, and support for rocket launches. In 2024, Meisei Electric's Navigation Camera contributed to the world's first successful pinpoint landing of the Smart Lander for Investigating Moon (SLIM). As the world's only manufacturer of comprehensive environmental observation systems, we will continue to open doors to the future in the space field.

Number of products introduced

Meisei Electric's Components

Launched into Space

In the 70 years of Meisei Electric's space business, we have participated in domestic and international space development projects, including the onboard equipment of Japan's first satellite, Ohsumi. More than 3,000 components continue to leave their mark in space.

-

Space Probe

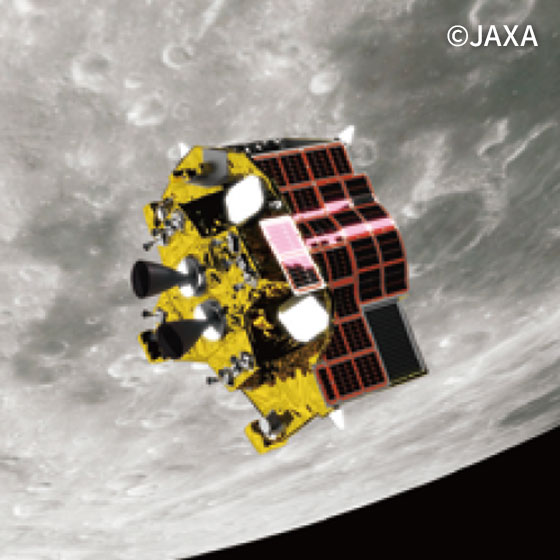

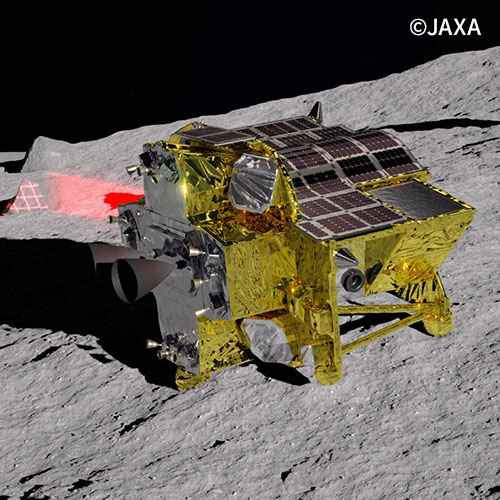

Equipment Onboard the Smart Lander for Investigating Moon (SLIM)

We worked on three pieces of equipment onboard the Smart Lander for Investigating Moon (SLIM). Our Navigation Camera contributed to the image-matching navigation for the world's first pinpoint landing by playing the role of "eyes," and our Multi-Band Camera observed the composition of rocks exposed on the lunar surface.

-

Space Station

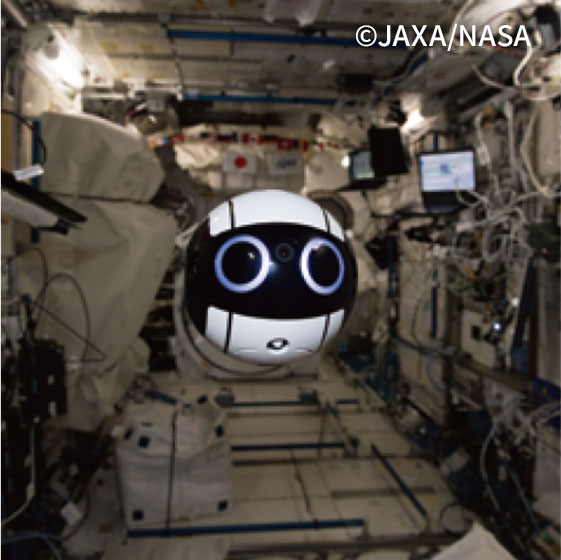

JEM Internal Ball Camera (Int-Ball)

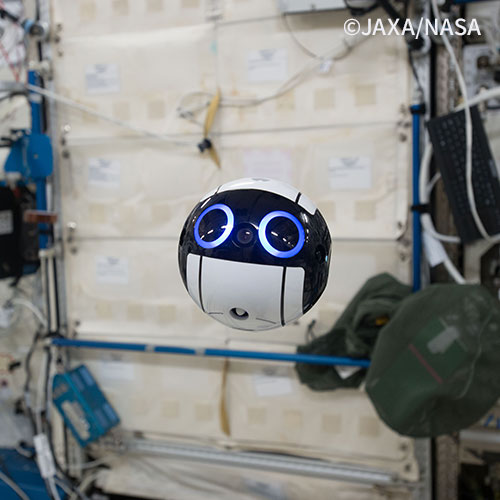

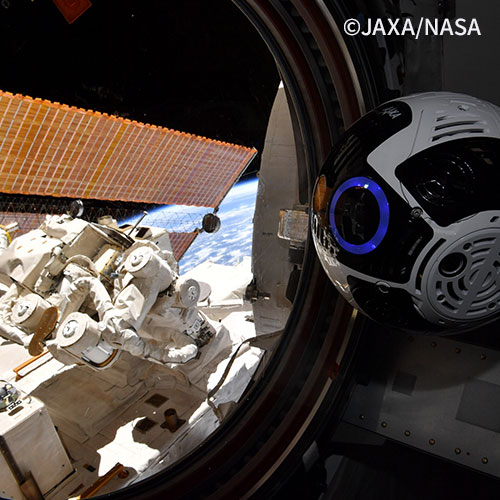

This camera was developed to improve efficiency by reducing the time astronauts spend preparing and taking pictures with a handheld camera while working inside the Japanese Experiment Module (JEM) "Kibo" of the International Space Station. Remotely controlled from JAXA's Tsukuba Space Center, it can move autonomously and take still and video images.

-

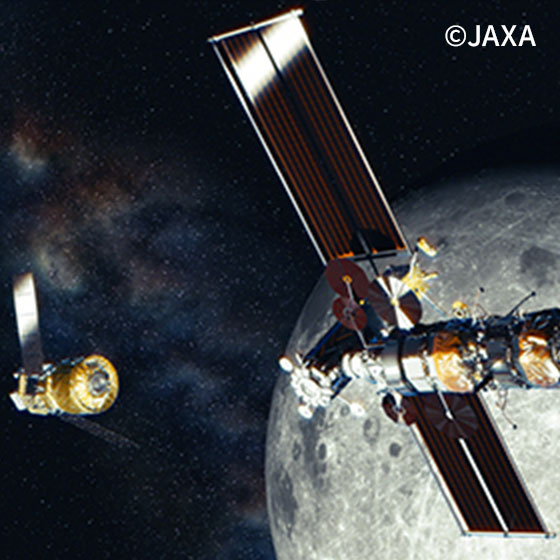

Gateway

Low Velocity Dust Monitor (LVDM)

We are working with JAXA to develop the Low Velocity Dust Monitor (LVDM) for installation on the lunar-orbiting space station (Gateway).

To measure the environment during the Gateway's early stages, LVDM will observe cosmic dust and lunar regolith flying into lunar orbit with pressure sensors. -

Rocket

Equipment Onboard the Epsilon Launch Vehicle

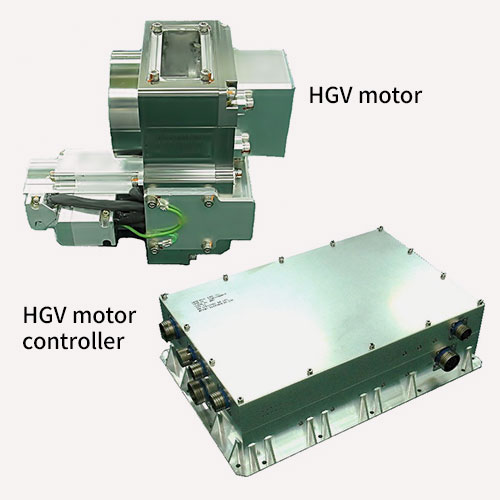

The Epsilon Launch Vehicle is equipped with Meisei Electric's rocket-mounted camera, Hot Gas Valve (HGV) motor controller for attitude control, and Power Sequence Distribution Box (PSDB).

Core Advantages

To function "as a matter of course" in space.

Basic Technology

A high level of environmental resistance is essential for operation in outer space. Equipment must continue to function properly in special environments. Therefore, not to mention incorporating basic technologies such as vibration- and heat-resistant structures, it must be determined whether the equipment can withstand the space environment through rigorous verification. Meisei Electric supports such evaluation criteria with its sophisticated space-related technologies and extensive test and verification facilities, thereby contributing to the success of space missions.

-

Environmental Resistance

Our extensive experience and know-how enable us to achieve environmental resistance that can withstand harsh space environments, such as vibration- and shock-resistance, radiation resistance, and electromagnetic compatibility.

-

Design and Analysis

We have a system that allows us to perform the following processes in-house, from design to analysis, necessary to develop space products.

- System design

- Electrical design

- Structural design

- Thermal design

- Structural analysis

- Thermal analysis

-

Test Environment Equipment

Meisei Electric has its own equipment that can simulate space environments (high vacuum, cold and dark) on Earth and evaluate environmental resistance, thermal design, performance, and more.

- Thermal vacuum/thermal balance test equipment

- Vibration test equipment

-

Diversion of Consumer Parts

Meisei Electric uses its own environmental test equipment to evaluate the environmental resistance of parts, and is also working on using consumer parts in space development. This has allowed us to shorten development times and reduce costs.

One stop to space.

Meisei Electric manufactures space observation equipment under an integrated production system from design to maintenance, and has sent more than 3,000 components into space.

We will continue to provide highly reliable products in the future through the know-how we have cultivated along with the history of space development and strict quality control.

Meisei Electric will continue to support your projects to the best of our ability.

Technology

01Camera Spectrometric

Conducts a distribution survey of hydrous minerals on the asteroid Ryugu.

Contributes to the mission of spectroscopic observations of olivine-bearing rocks on the Moon

Captures images of the lunar surface for image-matching navigation, contributing to pinpoint landing

Cameras onboard H-IIA and H-IIB rockets

Separation of solid rocket booster photographed from H-IIA rocket

High-resolution observation with GSD of less than one meter is possible from Super Low Earth Orbit

Meisei Electric's "eyes" made pinpoint landing on the Moon a reality.

Visible light camera technology

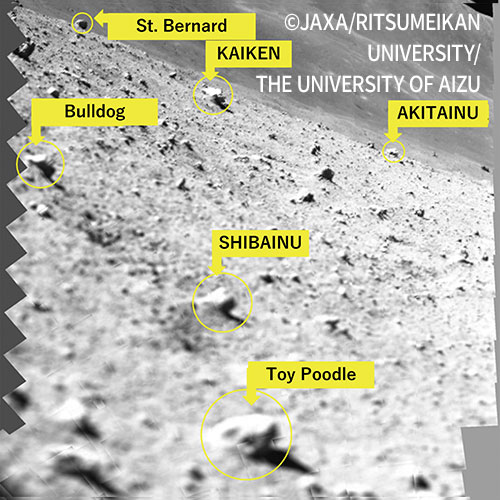

Many people may feel as if they are seeing the Earth and asteroids with their own eyes when they see real images of them in news reports and other media. Such images are captured by visible light cameras, which record images and video using light that can be seen by the human eye (visible light). Meisei Electric's SLIM Navigation Camera accurately captured craters (the lunar surface) even in the special environment of the lunar surface, and supported the successful pinpoint landing on the Moon by image-matching navigation. DCAM3 on Hayabusa2 captured images of the spreading ejecta from the asteroid Ryugu, and the high-definition camera on the lunar orbiter Kaguya captured images of "Earthrise," the appearance of the Earth from the lunar horizon. In this way, Meisei Electric's cameras served as the eyes of the artificial satellite and the researchers.

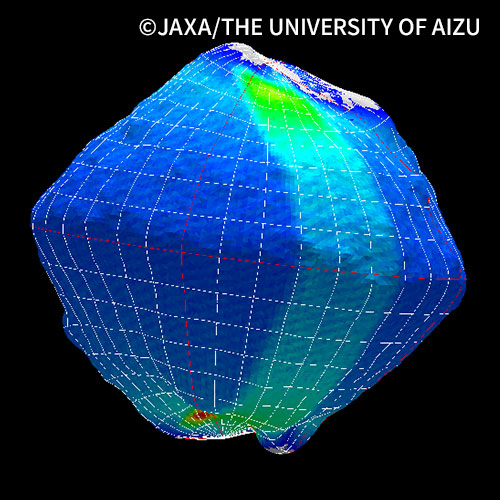

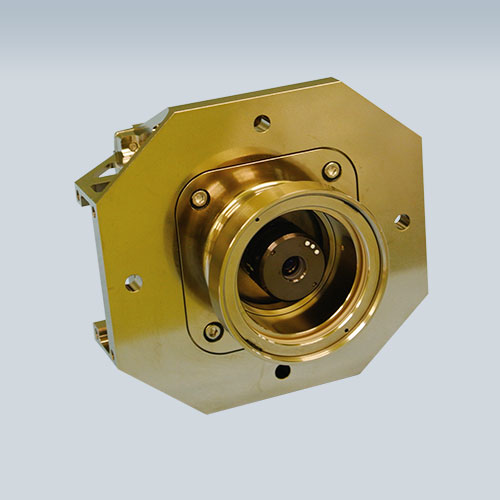

Spectroscopic camera technology

Spectroscopic cameras can capture data at specific wavelengths. Meisei Electric develops custom-made spectroscopic cameras that capture specific wavelength bands. For example, the SLIM Multi-Band Camera observed 10 bands in the wavelength range from 750 nanometers to 1,650 nanometers at a high resolution of 0.13 cm/pixel from a distance of 10 meters to study the composition of lunar olivine. We have developed a Near-Infrared Spectrometer for Hayabusa2 to investigate the water that existed when the solar system was formed, a thermal infrared camera called TIRI for HERA to understand the thermal properties of asteroids, and a Near-Infrared Spectrometer called ALIS for LUPEX to investigate water resources in the polar regions of the Moon. The valuable data obtained is analyzed by researchers in Japan and abroad, making a significant contribution to the scientific exploration of space.

Toward new space exploration.

Meisei Electric continues to contribute to unraveling the mysteries of the planets with its eyes.

Meisei Electric will continue to rise to the challenge of developing various types of mission equipment to further unravel the mysteries of space. For example, cameras that will contribute to lunar exploration and development. Clearer and more precise. Leveraging the know-how we have cultivated, we will continue to refine our technology to capture various phenomena in space through images and wavelengths.

-

Project : SlimSmart Lander for Investigating Moon (SLIM)

Succeeded in the world's first pinpoint landing (soft landing on the Moon) in January 2024. Spectroscopic observations were made with our Multi-Band Camera on 10 rocks, more than originally planned. After enduring the harsh lunar environment and surviving three nights, lunar operations ended in August of that year.

-

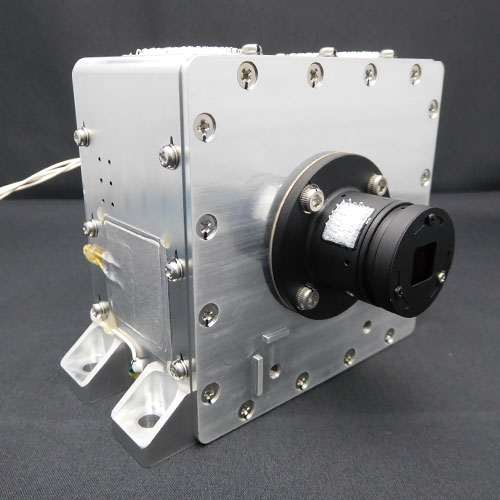

Navigation Camera (CAM)

Contributed as the "eyes" in image-matching navigation for the world's first pinpoint landing.

-

Multi-Band Camera (MBC)

Observed the composition of rocks exposed on the lunar surface.

-

Laser Range Finder (LRF)

Measured the distance between SLIM and the lunar surface. Knowing the distance contributed to a safe landing.

-

Navigation Camera (CAM)

-

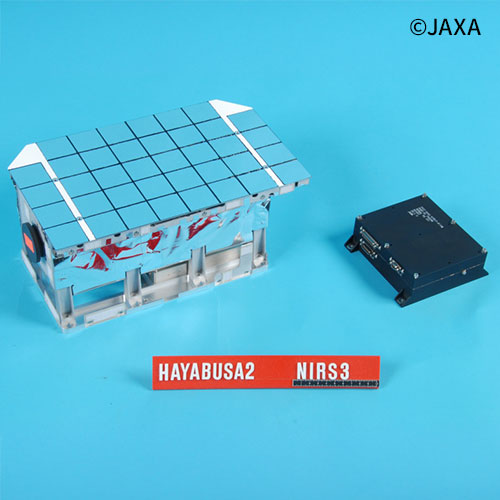

Project : hayabusa 2Asteroid Explorer Hayabusa2

Successfully touched down on the asteroid Ryugu in 2019, collected samples from Ryugu's surface, and was successfully recovered on Earth in December 2020. Currently, it has moved to the "Extended Mission" and is scheduled to observe asteroid 2001CC21 in 2026 and asteroid 1998KY26 in 2031.

-

Near-Infrared Spectrometer (NIRS3)

Discovered the presence of water-bearing minerals on the asteroid Ryugu.

-

Deployable Camera (DCAM3)

Successfully captured high-resolution images of the crash test.

-

Near-Infrared Spectrometer (NIRS3)

Custom-made

We are also available for joint development, custom design, and customization.

Depending on the nature of the project, we can design and manufacture spectroscopic cameras tailored to various wavelength bands that can measure even in harsh space environments. We also welcome consultation on joint development, customization, and more to meet your goals.

First, please contact us using the form below.

Technology

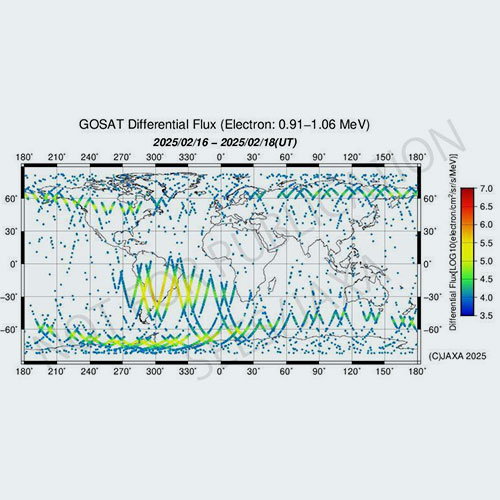

02Particle Measurement

Particle observation technology plays an important role at the forefront of space science.

silicon sensor

Utilizing the semiconductor properties of silicon to measure electrons and protons in outer space.

Silicon sensors are radiation detectors using silicon semiconductors.

It uses silicon’s semiconductor properties to detect the electric charge generated when alpha particles, beta particles, gamma rays, X-rays, and other radiation enter silicon, to measure particle energy in outer space.

proportional counter

A type of gas-filled detector.

Measures electrical signals proportional to radiation energy.

Gas is sealed in a metal cylinder and an appropriate high voltage is applied to the internal drift plane and shaping frame in the cylinder to create a uniform drift electric field within the sensitive volume. When charged particles enter the sensitive volume, the sealed gas is ionized and an electron cloud is formed along the trace. By observing the pattern of the electron cloud moving downward in the drift electric field, the trace of the incident particle is measured in 3D, and the LET (= energy deposit) is measured with high precision.

piezoelectric sensor (PZT)

Converts vibration and pressure into electrical signals to measure dust in outer space.

Pressure sensors use the piezoelectric effect, which generates a voltage when pressure or vibration is applied, to measure the concentration and particle size distribution of dust floating in outer space. The vibrations and pressure generated when dust particles collide with the sensor surface are converted into electrical signals and then analyzed for size and shape.

Micro-channel plate (MCP)

Measures incident particles using time-of-flight (TOF) analysis.

The incident particle is passed through an ultra-thin carbon film, and the velocity of the incident particle is derived from the detection time of the secondary electrons generated during the passage and the incident particle itself. The mass of the particle is measured from the derived velocity and the energy velocity of the particle.

Scintillator & Photomultiplier Tube

Measures energy using a scintillator, which captures radiation as light, and a photomultiplier tube.

A scintillator absorbs high-energy radiation, such as γ-, X-, and α-rays, and emits light. The light is injected into a photomultiplier tube, which consists of an incident window, photocathode (cathode), focusing electrode, electron multiplier (dynode), and anode, and the signal is measured to measure high-energy particles.

Toward the dream of lunar development. Meisei Electric's particle measurement technology ensures the safety and security of human space development.

Humanity's dream of lunar development is about to be realized after 2030.

It is essential to monitor the radiation coming from outer space for future humankind to operate safely and securely in space.

Meisei Electric will continue to contribute to the development of space by watching over the safety of human beings in space through the particle measurement technology in outer space that we have cultivated over the years.

-

Project : ISSInternational Space Station (ISS)

A huge manned experimental facility built about 400 km above the Earth. Construction began in space in 1998 and was completed in July 2011. The purpose of the ISS is to provide a place where various experiments and research can be conducted over long periods of time, taking advantage of the unique environment of space. Astronauts are still active on the ISS.

-

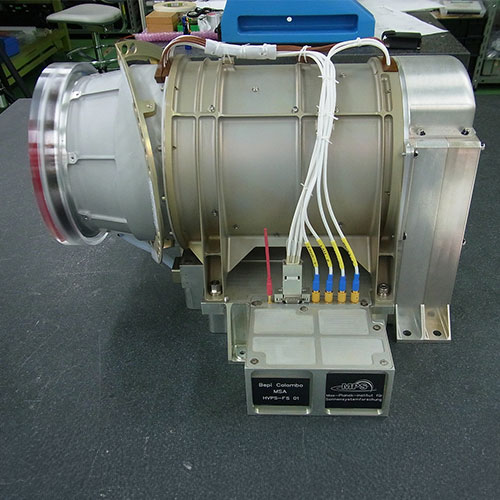

Position Sensitive Tissue Equivalent Proportional Chamber (PS-TEPC)

The ISS orbits at an altitude of about 400 km above the Earth, where it is exposed to radiation from space, and the length of time humans can stay in space is limited by the dose of radiation exposure. PS-TEPC accurately measures radiation from space in real time, contributing to the realization of long-term stays in space.

-

Position Sensitive Tissue Equivalent Proportional Chamber (PS-TEPC)

-

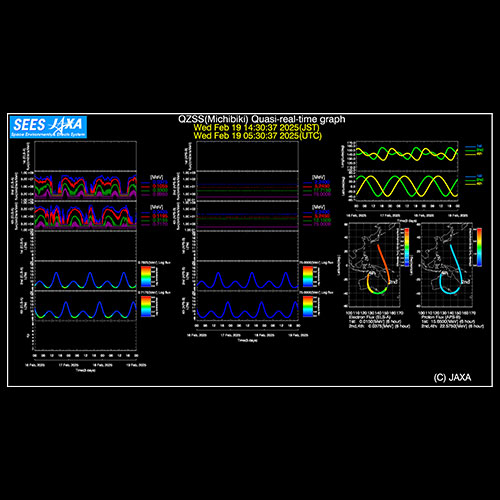

Project : QZSSQuasi-Zenith Satellite System (QZSS)

Nicknamed "Michibiki," a satellite positioning system for Japan and the Asia-Pacific region. It provides location information services for specific regions using artificial satellites with the same period as the Earth's rotation.

The first launch was in September 2010. Three additional satellites were launched in 2017, bringing the system to a four-satellite operation. Six satellites have been launched to date, and a seven-satellite system is expected to be operational by the end of FY2025.-

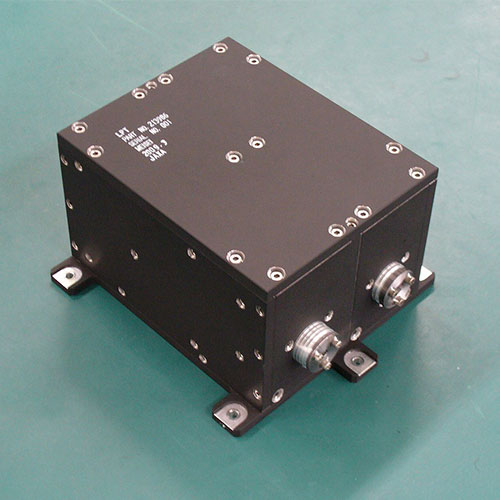

Space Environment Data Acquisition Equipment (SEDA)

SEDA has two types of sensors, the Light Particle Telescope Sensor (LPT-S) and the Magnetometer Sensor (MAM-S). The purpose of the observation is to obtain data that will contribute to evaluating malfunctions of the equipment onboard the satellite and investigating causes of malfunctions. The acquired data will also be reflected in satellite design. It was installed on the first, second, and fourth satellites.

-

Space Environment Data Acquisition Equipment (SEDA)

-

Project : ERGExploration of Energization and Radiation in Geospace (ERG) Satellite

Nicknamed "Arase," a geospace exploration satellite designed to make observations to elucidate the mechanism of the generation and annihilation of high-energy particles and the development of magnetic storms in the near-Earth radiation belt (Van Allen Belt). Since its launch in December 2016, it has successfully observed the radiation belt variations of numerous space storms of different scales.

-

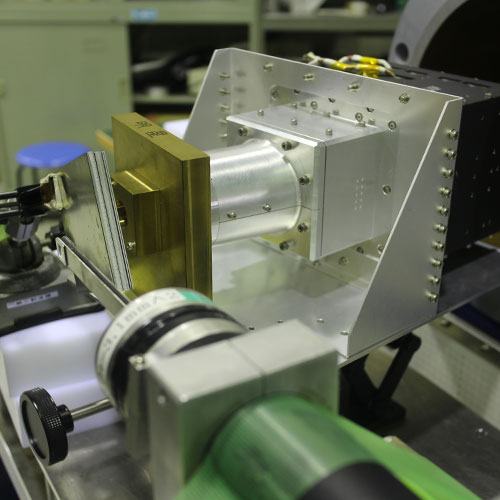

Extremely High-Energy Electron Experiment (XEP)

Consists of five semiconductor sensors and one scintillator. In energy measurement, the low-energy part detects energy with a semiconductor sensor, while the high-energy part uses a scintillator as well. The purpose is to realize integrated observations of particles, electromagnetic fields, and plasma wave motion at the equatorial geospace plane, where radiation belt electrons are accelerated, to study the mechanism of geospace fluctuations associated with space storms and the associated relativistic electron generations.

-

Extremely High-Energy Electron Experiment (XEP)

Custom-made

We are also available for joint development, custom design, and customization.

We can also consider custom design and mass production according to the required specifications of your project.

We are also happy to discuss customization to suit the satellite interface and launch vehicle conditions.

First, please contact us using the form below.

Technology

03Wireless technology

Enables download of high-quality space images over high-speed lines

First successful wireless LAN communication in space

Establish stable communications between satellites and the ground, and between space equipment.

We provide communications equipment that can withstand the harsh environment of space.

Durability is important in spacecraft operations. Meisei Electric's wireless communication systems are highly durable, suitable for use in outer space, and provide stable operation. We also offer products that use MIMO technology to improve communication efficiency. They can be used as transmitters for cameras and data recorders, providing a flexible solution for reliably transmitting data required for the mission back to Earth. Meisei Electric's wireless communication technology meets the diverse needs of space development.

MIMO: Multiple-Input Multiple-Output

A technology that improves the transmission capacity of wireless communications by allowing both the transmitter and receiver to use multiple antennas to communicate.

Our communications technology supports the satellite data that will change the future.

In recent years, the use of artificial satellites has increased dramatically. These satellites are equipped with high-performance cameras and SAR (Synthetic Aperture Radar) sensors for Earth observation and weather data collection, and are used in a wide range of applications, including global environmental monitoring, disaster response and improved agricultural efficiency. High-speed, highly reliable communications technology is essential for the rapid use of such valuable and vast amounts of data on the ground. There is also a growing need for broadband wireless receivers to enhance real-time information gathering and monitoring capabilities. To meet these needs, Meisei Electric has started developing multi-band receivers and will continue developing and supplying high-speed data transmitters and broadband receivers.

-

ProjectInnovative Satellite Technology Demonstration-4

This is the fourth demonstration opportunity under the Innovative Satellite Technology Demonstration Program, which provides space demonstration opportunities for components, equipment, CubeSats, and more developed by universities, research institutes, and private companies. Eight demonstration themes for components and equipment selected through an open call will be demonstrated in orbit on RApid Innovative payload demonstration SatellitE-4 (RAISE-4).

-

LEOMI

LEOMI (Low Earth Orbit Satellite MIMO and IoT Transmission Equipment) is an experimental satellite-mounted radio component for the demonstration as part of a joint research project between NTT and JAXA. We developed it based on orders from NTT and JAXA. It supports three-channel reception at 920 MHz IoT band and converts the received data into up to three-channel X-band MIMO transmission signals. This component will be used to demonstrate blind beamforming, IoT multi-protocol batch demodulation, and satellite MIMO technologies.

-

LEOMI

-

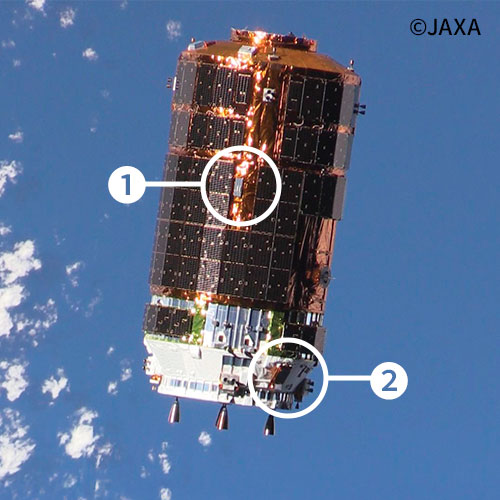

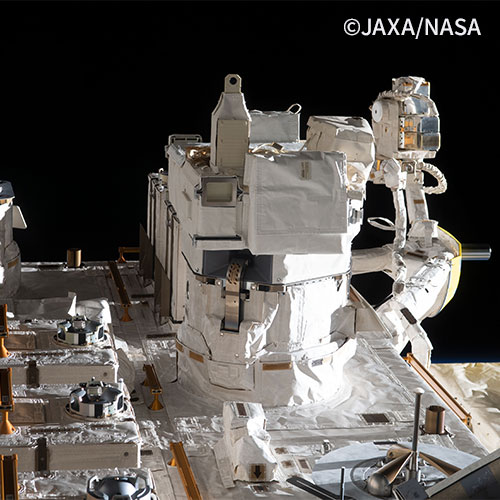

Project : HTV9Space Station Resupply Vehicle-9

Kounotori (H-II Transfer Vehicle: HTV) is an unmanned spacecraft developed by Japan to transport supplies to the International Space Station (ISS).

With one of the world's largest payload capacities of up to 6 tons, Kounotori can carry several large pieces of experimental equipment at once. In this way, it plays an important role in supporting ISS operations.-

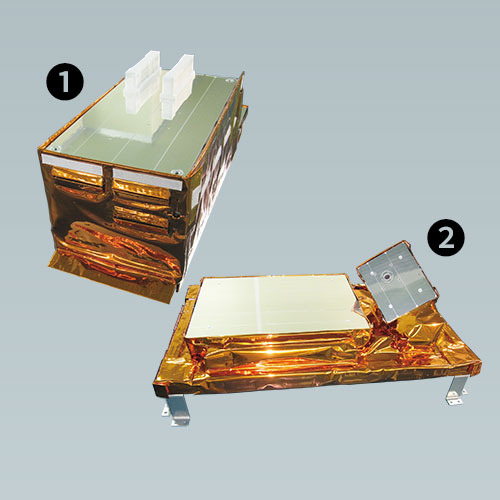

Wireless LAN Demonstration (WLD)

Meisei Electric has developed the camera system and wireless LAN transmission equipment mounted on Kounotori-9. The system consists of the PM surface mission assy and the ULC hole mission assy, and realized real-time video transmission between spacecraft. This technology is the first of its kind and will play an important role in future automated docking technology.

-

Wireless LAN Demonstration (WLD)

-

Project : SDS-4Small Demonstration Satellite-4

The Small Demonstration Satellite-4 (SDS-4) was launched by the H-IIA Launch Vehicle-21 to demonstrate new technologies in space. The mission included satellite reception of AIS signals, thermal control experiments with flat plate heat pipes, collection of solar absorptivity data using the French developed "THERME", and acquisition of operational results of a Quartz Crystal Microbalance (QCM).

-

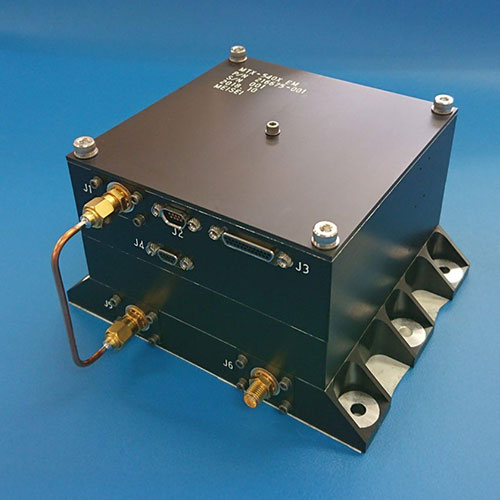

1 Mbps S-Band Transmitter

The S-Band Transmitter/Receiver is a communication device that provides two-way communication with the ground in the 2 GHz band. The 2-way Doppler function allows control of the transmission frequency, resulting in high-speed communication of 1 Mbps. It can switch between USB and QPSK transmission, and between coherent and incoherent mode, and constantly monitors the status of the transmitter/receiver.

-

1 Mbps S-Band Transmitter

Custom-made

We are also available for joint development, custom design, and customization.

We can also consider custom design and mass production according to the required specifications of your project.

We are also happy to discuss customization to suit the satellite interface and launch vehicle conditions.

First, please contact us using the form below.

Technology

04Control technology

Reliable technology to support motor control and communication control for various spacecraft

Meisei Electric's control technology supports the foundation of space development.

Control technology is critical to the success of outer space missions. In particular, accurate attitude control is required for rocket launches and work inside the space station. The Hot Gas Valve (HGV) and motor controllers used to control the Epsilon Launch Vehicle's attitude are key elements in achieving this precise control.

Innovative technologies that streamline work in space: Int-Ball and I-SEEP

The JEM Internal Ball Camera (Int-Ball) is used in the Japanese Experiment Module "Kibo" of the International Space Station to streamline astronauts' work. This camera moves autonomously and takes still and video images to support communication with the ground control center.

The IVA-replaceable Small Exposed Experiment Platform (i-SEEP) is designed to facilitate the installation of experimental equipment in outer space and can accommodate equipment up to 50 cm x 70 cm x 35 cm. This allows for various experiments and facilitates the development of new technologies.

Provide control technologies that drive space exploration for innovative rovers and robots.

Further advances in control technology in outer space are expected in the future. The development of autonomous control systems is expected to enable more efficient and safer mission execution. In addition, deploying new technologies is expected to make exploration and resource utilization in unexplored areas a reality. Meisei Electric will continue to contribute to space development by providing highly reliable control technology.

-

Project : KIBOUJapanese Experiment Module (JEM) "Kibo" of the International Space Station (ISS)

"Kibo" is one of the components of the International Space Station (ISS). It is Japan's first manned space experiment facility, and consists of five components, including the Pressurized Module for conducting experiments, the Exposed Facility, and the Robotic Arm for changing experimental equipment.

-

JEM Internal Ball Camera (Int-Ball)

This camera was developed to improve efficiency by reducing the time astronauts spend preparing and taking pictures with a handheld camera while working inside the Japanese Experiment Module (JEM) "Kibo" of the International Space Station.

Remotely controlled from JAXA's Tsukuba Space Center, it can move autonomously and take still and video images. -

IVA-replaceable Small Exposed Experiment Platform (i-SEEP)

The IVA-replaceable Small Exposed Experiment Platform (i-SEEP) can accommodate multiple instruments and provides an experimental or demonstration environment for the instruments. It supports experiments and demonstrations in space with reliable control.

-

JEM Internal Ball Camera (Int-Ball)

-

Project : EpsilonEpsilon Launch Vehicle

The Epsilon Launch Vehicle is a solid-fuel rocket developed by JAXA and IHI Aerospace to launch small satellites. It is considered a key launch vehicle to ensure the autonomy of Japanese satellite launches.

-

Hot Gas Valve (HGV)

The HGV-driven motor controller controls SMSJ for attitude control, providing highly accurate control of the vehicle as it is injected into orbit.

-

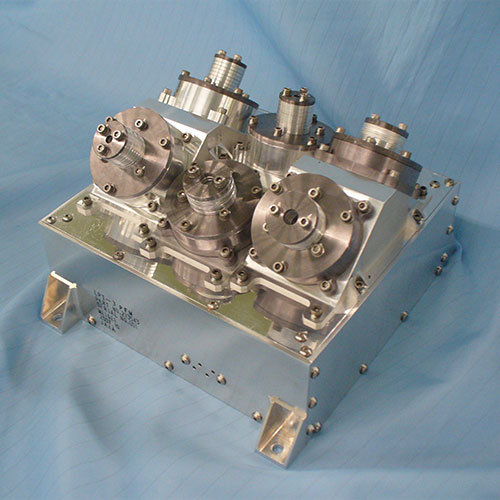

Power Sequence Distribution Box (PSDB)

PSDB efficiently distributes power from the battery to each instrument. The test model used a mechanical relay, but the reinforced model uses a semiconductor relay. The PSDBs installed on the second and third stages of the Epsilon Launch Vehicle have been made even smaller and lighter, and have been installed on up to the sixth launch vehicle. This improvement has reduced the burden on the entire launch vehicle, resulting in more efficient and reliable space missions.

-

Hot Gas Valve (HGV)

Custom-made

We are also available for joint development, custom design, and customization.

Depending on the nature of the project, we can design and manufacture control devices that can operate even in harsh space environments. We also welcome consultation on joint development, customization, and more to meet your goals.

First, please contact us using the form below.